The DQL-5545 can be added to an existing conveyor line or used by manually feeding the box/package onto the conveyor.

Center fold POF/PVC film is used to automatically dispense,wrap and seal over your desired products.

The operator manually sets the sealing length for the product to be wrapped.

The sealer has a safety system which immediately stops the sealing mechanism in the event the operators hand or object interfered

with the sealing operation.

The sealing mechanism has a non stick coating which results in a smoke free operation/All excess plastic is wound onto a dispenser below the machine which can easily be dispensed of.

Once the product is sealed it then automatically runs through the thermal shrink tunnel where the shrink film is heat shrunk tightly around products.

Features

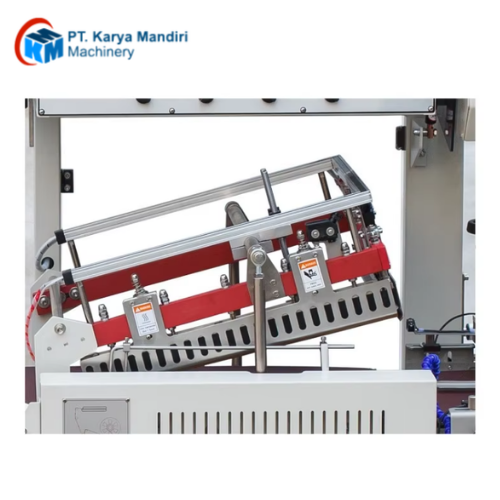

1. The sealing knife adopts copper alloy sprayed with teflon, it won’t stick film, sealing fastness, without smoke, non-pollution. Horizontal and vertical sealing knife adopt whole connecting without gap, the film won’t break. Sealing frame adopts high quality alloy steel, the sealing quality is stable, frame difficult to be damaged.

2. The machine has entire automatical system, it equiped with sensors can reach high speed automatical working.

3. It is convenient to adjust according to different sizes products, just adjust the handle wheel can reach it, operation is easy.

4.it can be connected with production

5.it has protection function to avoid sealing product wrong and ensure the safety of operator

Advantage

1.The fully automatic heat shrink packaging machine is widely used in the production of packaging lines and has high work efficiency.

2.The cutter adopts Teflon coating anti-adhesive and high-aluminum-bonded knife, the seal will not split, no coking, no smoke and zero pollution.

3.Equipped with imported detection optoelectronics and relays. (Using Omron optoelectronic).

4.Automatic feeding, the length is automatically adjusted by the delay switch.

5.Equipped with an induction motor to automatically take up scrap.

6.When the size of the package is changed, the adjustment is very simple, and there is no need to change the mold and the bag maker.

Applications

This machine Suitable for large quantity shrink wrapping industries such as stationery, food, cosmetic, pharmaceutical, metal industries etc, imported PLC automatic program control, easy operation, safety protection and alarm function, and effectively prevent incorrect, packaging, Equipped with imported horizontal and vertical detection photoelectric, easy to switch selection. It has the function of contact, specially designed for packing small size products. The machine can be connected with the production line, no need additional operators.

Parameter Data

|

Model

|

DQL5545

|

|

Power

|

2.1KW

|

|

Voltage

|

220V 50/60HZ

|

|

Sealing time

|

0.2-1.0s

|

|

Thickness of film

|

0.012-0.06mm

|

|

Compressor of work

|

5-6mpa

|

|

Max packing size

|

L+2H≤550mm;W+2H≤450mm;H ≤140mm

|

|

Max sealing size

|

L550×W450

|

|

Capacity

|

0-25 pcs/min

|

|

Sealing temperature

|

180℃-250℃ depends on thickness of film and environment temperature

|

|

Packing material

|

POF PVC

|

|

Machine weight(kg)

|

320

|

|

Machine size(mm)

|

1760*940*1580

|