BS-4535 equipped stainless steel heater and high power blowing motor ensure fast heat-up, large & even-distributed airflow in the tunnel. Both conveyor belt speed and temperature inside the tunnel are adjustable according to the product size and the output requirement in order to obtain the optimal shrinking effect. Features: √Variable conveyor speed control by [...]

In coordination with the respective packaging machine, we supply our customers with the suitable shrink tunnel. It communicates with the machine and is so well insulated that a large portion of the warmth remains in the tunnel and little energy is used.

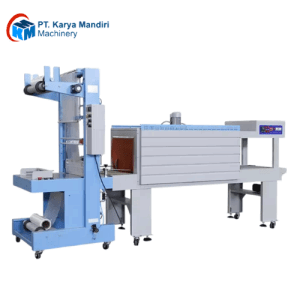

The shrink tunnel BS-4535LA supplies heated air to an enclosed chamber with the purpose of shrinking a polymeric film around a package.

BS-5530M Shrink tunnel with high thermal insulation and ample power for all types of shrink film including the film in PE.

BS-6535LA adopts hot-wind & down-cyclone structure, intelligence temperature control and AC variable speed regulation. There are two optional conveyors, including Teflon belt type and roller type.

The product can be fed manually or pneumatically. When the sealing & cutting cycle is complete, the product is discharged into the shrink tunnel automatically. The machine is used to shrink package single and multiple products.

These are adaptable machines, designed for production companies of every dimension and are ideal for solving problems related to the different packaging requirements.

Model BSF-6030XI+BS-6040L is ideal for packaging single and multiple products without tray. The machine can be integrated into a production line to complete the process of product infeed, film wrapping, sealing & cutting, shrinking and cooling automatically.