FEATURES

- Carton dragging by top belts and bottom belts with independent motors

- Side sealer specially designed for packing stations where the cartons are filled and the end and sealed lying down.

- Crank handle adjustment of carton width and height, easy operation and no need professional technicians

- Especially suitable for thin / flat /styrofoam size boxes side-seal

- Both side guides

- Can bear up to 30kg loading

- No air required to run the machine

- Stainless roller table for carton movement

- Carton sealing: top and bottom

- Two sides compression rollers, have better tightness

- The tape head is developed and produce by CHA PACK, the length of tape that can be placed up to 900m. (260mm diameter)

- Dual telescoping mast with cushion. Adjust the unevenness of the carton.

- Machine with mobile locking casters, easy to move anywhere

- Emergency stop on top taping head for quick access

- Parts are manufactured with mold.- Stable quality, Short lead time

- Machine can be available with other equipments, e.g: 1. Labeling mc. 2. Weighing mc. 3.Inkjet Printers

- Combine with case erector, or case strapper or pallet wrapper for end of line packaging automation

- Machines are designed and produced by ourselves. Rugged design, low maintenance rate

SPECIFICATIONS

| Model | CHS-6604 (Side-Seal) |

| Function | Top & bottom belt driven |

| Power Supply | 1 phase,110V/220V/240V |

| Tape Width | 2″ or 3″ |

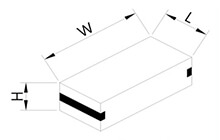

| 2” Tape Sealing size | L150-∞mm, W250-650mm, H110-250mm |

| 3” Tape Sealing size | L150-∞mm, W250-650mm, H135-250mm |

| Tape overlap | L60±5 (mm) standard |

| Working table height | 590-790mm |

| Control system | Traditional distribution |

| Conveyor Speed | 20 M/min |

| Capacity | 20~25 cases/per min. (Data is for carton length=330mm) *** Depending on box size and operator efficiency.*** |

| Machine dimension | L1100xW790xH1420mm |